Automatizáció blog

Őrizze meg biztonságát, és feleljen meg a szabályozásoknak: Az öt legfontosabb tipp az EU gépekről szóló rendeletére való felkészüléshez

2025. december 2. A kibertámadások valódi fenyegetést jelentenek a gyártási ágazatban, ahol megzavarhatják a termelést, károsíthatják a gépeket, és végső soron veszélybe sodorhatják a vállalkozásokat. Az Európai Unió új, gépekről szóló rendeletének (2023/1230/EU) célja – amely 2027 januárjában váltja fel a 2006/42/EK gépekről szóló irányelvet –, hogy segítse a gépek védelmét ezekkel a kockázatokkal szemben. A rendelet betartása az EU teljes területén kötelező. A gépgyártók számára ez azt jelenti, hogy a védelmet már a tervezés során be kell építeni. A végfelhasználók számára ez azt jelenti, hogy a berendezéseket nagy fokú éberséggel kell üzemeltetni és karbantartani. Íme öt fontos tipp, amelyek mindkét fél számára hasznosak lehetnek a jövőbeli követelmények teljesítéséhez és a fenyegetések kivédéséhez.

Az IT/OT közötti rés áthidalása: Gyakorlati lépések egy összekapcsolt jövő felé

2025. november 17. Napjaink ipari párbeszédét a mesterséges intelligencia, az adatgyűjtés, a digitális leképezések és az IT/OT konvergencia dominálják. Sok gyártó számára azonban egy kihívás továbbra is megoldatlan: a munkát megtervező vállalati rendszerek és a megvalósítást biztosító operatív technológiák közötti szakadék áthidalása. Az ERP-rendszerek és a MES-platformok továbbra is az egyik oldalon, míg a PLC-k, az érzékelők és a robotok a másik oldalon helyezkednek el. Az informatika (IT) és az operatív technológia (OT) évtizedek óta inkább párhuzamosan, mintsem együttesen fejlődtek. Az IT biztosítja az adatokat, az elemzéseket és a vállalati átláthatóságot; az OT pedig a gépek üzemeltetését, a gépbiztonságot, és a gyártás megbízhatóságát. Mindkettő elengedhetetlen, de gyakran a vállalati szinten generált adatok nem jutnak vissza a gyártórészleghez, míg az értékes működési adatok is a mérnöki csapatok körében maradnak meg. Ennek eredményeként a digitális átalakulás teljes ígérete elérhetetlen marad. Ez a szakadék már nem csupán technikai, hanem stratégiai. A gyártók folyamatos nyomással szembesülnek, hogy gyorsabban alkalmazkodjanak a változó kereslethez, a rövidebb innovációs ciklusokhoz és a növekvő fenntarthatósági elvárásokhoz. Ezek a célok nem érhetőek el, ha a digitális és fizikai rendszerek továbbra is egymástól elszigetelten működnek. Egyes automatizálási beszállítók már megkezdték az IT- és OT-megoldások együttes fejlesztését, de a valódi versenyképesség ma már az iparágak legjobb szakértőit összefogó együttműködésen és a közös alkotáson múlik. Hogyan tudnak tehát a gyártók a koncepciótól eljutni a megvalósításig? Az OMRON tapasztalatai és az iparágak közötti együttműködéseink alapján négy gyakorlati módszert mutatunk be az IT/OT konvergencia felgyorsítására.

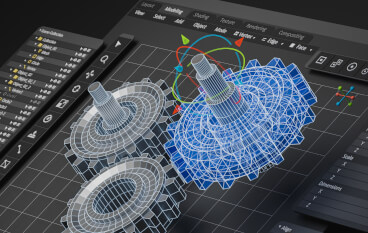

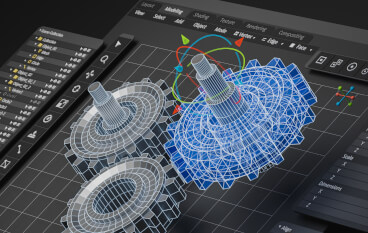

Virtuális üzembe helyezés: A költségek csökkentése és a géphitelesítés javítása

2025. október 1. „Nem beszéltünk róla, mert azt hittem, hogy tudod” – egy olyan mondat, amit az évek során sokat hallottam. A nem megfelelő kommunikáció az első számú oka annak, hogy az ipari automatizálási projektek az üzembe helyezés szakaszában nem mennek a terv szerint. Legyen szó új gépről, új celláról vagy egy teljes gyártósorról, gyakran félreértések merülnek fel a projektpartnerek között a terv kivitelezésével kapcsolatban. A dokumentációval kapcsolatos konzultáció nem mindig segít, mert gyakran a pontatlan, nem egyértelmű vagy hiányos információk okozzák a nézeteltérést. Jó példa erre a bemenetek, kimenetek és interfészek közötti hibás kommunikáció. A rendszerintegrátor feltételezheti, hogy egy berendezés EtherCAT-et használ, míg a gyártó a Profinetet várná el. Vagy talán egy gyártósor-integrátor elfelejt megemlíteni egy érzékelőt, amely a gép biztonsága szempontjából fontos kiegészítő információkat rögzít. Mindkét esetben ugyanaz az eredmény: többletköltségek, elvesztegetett idő és növekvő frusztráció minden érintett fél számára. A megoldás egyszerű: ne hagyja, hogy az emberek egyedül hozzák létre a specifikációkat. A virtuális üzembe helyezés sokkal pontosabb specifikációkat eredményez.

5 adatterület, amelyet már most is nyomon kellene követnie a gyártósorain

2025. szeptember 5. Valószínűleg hallotta már a „digitális átalakulás”, az „intelligens gyár” és az „adatvezérelt döntéshozatal” kifejezéseket, és a felénél már valószínűleg elvesztette a fonalat. Ez a legtöbbünk számára egy rendkívül új világ. Azonban a gyártóipar komoly szereplői, akik megőrzik versenyképességüket, teljesítik az üzemidőcélokat és megőrzik a haszonkulcsukat, néhány kulcsfontosságú adatot pontosan nyomon követnek. Nem az összeset, csak azokat, amelyek számítanak. Ha Ön ezeket nem kíséri figyelemmel, akkor valószínűleg túl sokat költ, túl sok a vesztesége, vagy csak vakon cselekszik. Stefan Jensennel, az OptiPeople vezérigazgatójával, egy olyan vállalat vezetőjével beszélgettünk, amely mélyen beleásta magát a termelési adatok világába, és öt alapvető kategóriába sorolta az adatokon alapuló termelést. Mindegyik elég egyszerű, de ha nem cselekszik, akkor a legközelebbi versenytársai le fogják hagyni.

Egyedi gépek: moduláris tervezés integrált környezetben

2025. szeptember 2. Napjaink felgyorsult ipari környezetében egyre nagyobb az igény az egyedi gépek iránt. A gépgyártóknak szembe kell nézniük azzal a kihívással, hogy egyedi gépeket állítsanak elő az ügyfelek speciális igényeire szabva. A számos variáció miatt ez a fejlesztés, az üzembe helyezés és a karbantartás hatékonyságának csökkenéséhez vezet. Az OMRON integrált fejlesztési környezetét (Integrated Development Environment – IDE) biztosító Sysmac Studio olyan megoldást kínál, amely leegyszerűsíti a gépfejlesztési folyamatot. Olyan környezetet, amely serkenti a programozók kreativitását és teljes potenciálját.

5 praktikus módszer az intelligensebb, keskenyebb és megbízhatóbb vezérlőpanelek építéséhez

2025. augusztus 5. Ha valaha is belenézett egy ipari gyártósoron lévő gépbe, valószínűleg látott már vezérlőpanelt. Ez az a strukturált tér, ahol tápegységek, relék, csatlakozók és vezérlők kapnak helyet. A vezérlőpanelek létfontosságú elemek, amelyek biztosítják a gépek működését, a folyamatok megvalósulását és a gyártósorok rendeltetésszerű működését. De a modern vezérlőpanelek sokkal többre lehetnek képesek, mint csupán az alkatrészek tárolására. Ha a megfelelő megközelítést alkalmazzuk, hozzájárulnak az építési idő csökkentéséhez, az anyagfelhasználás minimalizálásához, javítják a helykihasználást, és növelik a rendszerek hosszú távú megbízhatóságát.

Hogyan építsünk rugalmasságot minden gyártási döntésbe?

2025. július 17. Gyarapodás a kihívásokon keresztül: Hogyan építsünk rugalmasságot minden gyártási döntésbe?A mai világban az alkalmazkodóképesség már nem csupán versenyelőny, hanem szükségszerűség. A különböző ágazatokban a gyártók folyamatos zavarokkal küzdenek: változó jogszabályok, kiszámíthatatlan kereslet, változó ellátási láncok, növekvő munkaerőhiány és képzettségi különbségek. A rugalmasság nem lehet másodlagos szempont. Be kell építeni a rendszerbe, be kell ágyazni a stratégiába, valamint technológiai és kulturális eszközökkel kell megerősíteni.Az alábbiakban bemutatunk öt alapelvet, amelyek segítségével a rugalmasság beépíthető a gyártási folyamatokba:1. Az ügyfelek és a partnerek előtérbe helyezéseA rugalmas gyártóknak egy közös vonásuk van: a hosszú távú kapcsolatokat helyezik előtérbe. Tapasztalataink szerint az ügyfelekkel és a technológiai szolgáltatókkal kialakított szoros partnerségek olyan bizalmi alapot teremtenek, amely zavarok esetén felbecsülhetetlen értékűvé válik. Ez az alap idővel egyre szilárdabbá és erősebbé válik. Akár globális alkatrészhiányról, akár hirtelen szabályozási változásról van szó, a nyitottsággal, lojalitással és együttműködéssel működő vállalatok gyorsabban és hatékonyabban reagálnak. Ezek az emberi kapcsolatok ugyanolyan fontosak a rugalmaság szempontjából, mint bármely gép vagy rendszer.

Szimuláció: a koncepciótól a virtuális másolatig

2025. június 4. Hogyan használhatják ki a gyártók a szimuláció erejét annak érdekében, hogy a való világbeli tervezést már az első alkalommal helyesen valósítsák meg? Maga a koncepció, hogy szimulációt használjanak a gyárak tervezéséhez, már évek óta létezik, sőt, még a számítógépek előtt is létezett. A szimuláció legkorábbi példái kézzelfogható modellek voltak, amelyek lehetővé tették a mérnökök számára, hogy kisebb méretben teszteljék a folyamatokat és a terveket, mielőtt élesben alkalmazták volna azokat. Bár ugyanazok az alapelvek még mindig érvényesek, manapság a szimuláció virtuális környezetben zajlik. Ez sokkal nagyobb kapacitást biztosít arra, hogy összetett folyamatokat hozzanak létre annak érdekében, hogy teszteljék, miképp befolyásolják a változó tényezők az eredményeket. Az AI-alapú technológiák nagyban hozzájárultak a rugalmasság és a kifinomultság ezen szintjének eléréséhez.

Hogyan tervezzük meg a gépek integrált biztonsági rendszerét már az üzembe helyezés előtt?

2025. május 20. A biztonság minden modern gyártó- vagy csomagolósor létfontosságú eleme. A biztonsági rendszerek megvédik a munkavállalókat, és megakadályozzák, hogy a meghibásodások kárt tegyenek az értékes termékekben és berendezésekben. Ha probléma merül fel, egy jó biztonsági rendszer leállítja a gyártósort, hogy elkerülje a lehetséges baleseteket, ami lehetővé teszi a gyártósor gyors újraindítását is.

A manuálisan végrehajtott funkcionális biztonsági ellenőrzésektől az irányított tesztelésig: a biztonsági ellenőrzés korszerűsítése

2025. május 6. A funkcionális biztonság minden ipari automatizálási rendszer esetében alapvető fontosságú. A vészleállító gomboktól kezdve a reteszeken át a fényfüggönyökig a biztonsági alkatrészek és a biztonsági lánc feladata az emberek védelme, valamint a gép integritásának és a szabályozásoknak való megfelelés biztosítása. Annak ellenőrzése azonban, hogy ezek a rendszerek megfelelően működnek-e – különösen a gépek üzembe helyezése és a teljes élettartamuk során történő karbantartása során – továbbra is összetett és időigényes feladat marad, amely sok gyárban magas költségekkel jár.

Termék- és folyamattervezés – digitálisan

2025. április 10. A forgatókönyv a következő: Ön egy gyártó, aki egy új terméket szeretne kifejleszteni, és a gyártáshoz egy új gyártósorba kell beruháznia. Olvasott a digitalizáció előnyeiről, és szívesen alkalmazna egy high-tech megközelítést. Hol kezdje?Ha új terméket fejleszt, és új gyártósorra van szüksége, az első alapelv az, hogy a terméktervezés határozza meg a folyamattervezést, és nem fordítva. A második, hogy mindkettő párhuzamosan történik, ami egy digitális gyárban csökkenti a piacra kerülési időt.

Észrevehetetlen innováció: digitális vízjelek + ipari automatizálás

2025. március 20. A modern gyártásban a termékek pontosságának, minőségének és fenntarthatóságának biztosítása fontosabb, mint valaha. A rendkívül hatékony, ugyanakkor az emberi szem számára észrevehetetlen digitális vízjelek ígéretes technológiát jelentenek, különösen ipari automatizálási megoldásokkal kombinálva. Fokozzák a nyomonkövethetőséget, és megoldást kínálnak a hagyományos kódok, például a QR- és a DataMatrix-kódok bizonyos korlátaira. Bemutatjuk, hogyan alakítja át ez a technológia a gyártást.

Őrizze meg biztonságát, és feleljen meg a szabályozásoknak: Az öt legfontosabb tipp az EU gépekről szóló rendeletére való felkészüléshez

2025. december 2. A kibertámadások valódi fenyegetést jelentenek a gyártási ágazatban, ahol megzavarhatják a termelést, károsíthatják a gépeket, és végső soron veszélybe sodorhatják a vállalkozásokat. Az Európai Unió új, gépekről szóló rendeletének (2023/1230/EU) célja – amely 2027 januárjában váltja fel a 2006/42/EK gépekről szóló irányelvet –, hogy segítse a gépek védelmét ezekkel a kockázatokkal szemben. A rendelet betartása az EU teljes területén kötelező. A gépgyártók számára ez azt jelenti, hogy a védelmet már a tervezés során be kell építeni. A végfelhasználók számára ez azt jelenti, hogy a berendezéseket nagy fokú éberséggel kell üzemeltetni és karbantartani. Íme öt fontos tipp, amelyek mindkét fél számára hasznosak lehetnek a jövőbeli követelmények teljesítéséhez és a fenyegetések kivédéséhez.

Eligazodás a berendezésekről szóló új szabályozásban

2025. január 16. Az Európai Unió 2027. január 20-tól a berendezésekről szóló 2006/42/EK irányelvről áttér az új, berendezésekről szóló rendeletre (2023/1230/EU), amely jelentős változást jelent a berendezésekre és a kapcsolódó termékekre vonatkozó jogszabályi követelmények terén. A rendszerintegrátorok számára a rendelet szigorúbb követelményeket vezet be az AI-vezérelt rendszerek, az autonóm berendezések és az összekapcsolt berendezések beépítésére vonatkozóan. A végfelhasználók, különösen az összetett géprendszereket működtető felhasználók számára stratégiai fontosságú az ezekre a változásokra való felkészülés.

Az optimalizálástól az autonómiáig – A 2025-ös év öt legfontosabb gyártásautomatizálási trendje

2025. január 4. Ahogy belépünk 2025-be, az ipari automatizálás világa új fejezethez közeledik. Az OMRON SINIC-elmélete szerint, amely a technológia fejlődést a társadalmi változáshoz köti, az optimalizáló társadalom felől elmozdulunk az autonóm társadalom felé. Az OMRON alapítója, Kazuma Tateishi által 1970-ben megalkotott elmélet alapján a jövőbeli társadalmi és technológiai fejlődések fognak irányt mutatni az innovációnak. A működés javítása érdekében az optimalizálási fázisban a hangsúly a folyamatok finomítására, a hatékonyság növelésére és a technológia felhasználására helyeződött. Az autonóm társadalom azonban egy teljesen új korszak – egy olyan, amelyben a rendszerek nem csak hatékonyan működnek, hanem önszabályozóvá, öntanulóvá és önálló döntéshozatalra képessé válnak.

Mi várható az automatizálás terén 2024-ben? Az OMRON Europe hat, a műszaki változásokat előrevetítő irányvonalainak előrejelzése

2023. december 13. Az elmúlt néhány évben bekövetkezett megrázkódtatások sorozata a fokozott geopolitikai és gazdasági kockázatok új korszakát hozta el. Ez arra készteti a gyártókat, hogy az üzleti modelljeiket alkalmazkodóbbá és rugalmasabbá tegyék, és újragondolják a globális ellátási láncaikat és üzleti kapcsolataikat. Ezzel egyidejűleg egyre nagyobb a nyomás, hogy az ESG (Environmental, Social, Governance) környezeti, szociális és vállalatirányítási elveket beépítsék az operatív döntéshozatalba. A mesterséges intelligencia, az adattudomány, a gyártás digitális leképezése (digital twins) valamint az érzékelő, megfigyelő és képalkotó technológiák mind-mind alapvető fontosságúak lesznek az automatizálási és vezérlési megoldások kifejlesztéséhez, amelyek segíthetnek a gyártóiparnak alkalmazkodni ehhez az új valósághoz. Ebben az összefüggésben szeretném megosztani a hat legfontosabb trendet, amelyek 2024-ben és azon túl is hatással lesznek az ipari automatizálásra és alakítani is fogják majd azt.

A munkaerő fontosságának növelése: Az OMRON fejlesztési koncepciója az európai gyártásban

2023. szeptember 6. Bemutatjuk az OMRON megingathatatlan elkötelezettségét a jövő nemzedékét támogató készségek fejlesztése iránt, miközben az iparág az átalakulás útjára lép – egy olyan útra, amely feltárja a negyedik ipari forradalom (4IR) minden lehetőségét, mialatt bátran halad az ötödik ipari forradalom (5IR) felé.Az egyetemi tantermekben, az újító szellemű üzleti vezetők tanácstermeiben és a jövőbe tekintő politikusok tárgyalótermeiben heves viták folynak. Ezek a viták arról szólnak, hogy a negyedik ipari forradalomról (4IR), vagy ahogyan más néven nevezik, az Ipar 4.0-ról az Ipar 5.0-ra való gyökeres átállás, meg fogja változtatni a világot, amelyben élünk.Történelmileg az ipari forradalom volt az első gépkorszak, az elektromosság a második, az elektronika a harmadik, az internet mint platform pedig a negyedik. Most lépünk be az ötödik gépkorszakba, amely az ember és a gép harmonikus együttműködését és az ipar társadalomhoz való hozzájárulását helyezi előtérbe. Itt a pillanat, hogy ne csak alkalmazkodjunk, hanem vezető szerepet töltsünk be, úttörő szerepet vállaljunk, és olyan jövőt teremtsünk, amelyben az innováció nem ismer határokat. Klaus Schwab, a Világgazdasági Fórum alapítója és ügyvezető elnöke megjegyezte: "Egy olyan technológiai forradalom küszöbén állunk, amely alapjaiban változtatja meg az életünket, a munkánkat és az egymáshoz való viszonyunkat. Méretét, hatókörét és összetettségét tekintve ez az átalakulás semmihez sem fog hasonlítani, amit az emberiség eddig tapasztalt." Világunk átalakulóban van. A globális termelés fejlődik, amelyet a hagyományos ipari gyakorlatok automatizálása vezérel az intelligens technológia, az M2M (machine to machine) kommunikáció és az IoT integráció révén. Ez a szinergia hajtja az automatizálást, a zökkenőmentes kommunikációt és az intelligens gépeket, amelyek önállóan elemzik és diagnosztizálják a kihívásokat.A mesterséges intelligencia térnyerése vitákat vált ki, és mélyebb átalakulásokra utal társadalmunk szerkezetében. Miközben ezen a mozgalmas terepen haladunk keresztül, közben már készen állunk az innováció befogadására és a jövőnk átalakítására.

A piros jelzőlámpától a robotokig: az OMRON az innováció 90. évfordulóját ünnepli

2023. június 6. Ebben az évben, az Alapítók Napján az OMRON visszatekintett a technológiai határok feszegetésével töltött 90 évére, majd előretekintett az automatizálási innováció jövője felé, amelyet a fenntarthatóság, a digitalizáció és az ember-gép együttműködés jellemez.Ünnepeljük együtt május 10-ét Május 10. minden évben valószínűleg a legfontosabb nap az OMRON naptárában. Ezen a napon világszerte 30 000 OMRON-alkalmazott ünnepli a vállalat alapítójának, Kazuma Tateishinek az életét és örökségét. Ezt úgy teszik, hogy újra elkötelezik magukat Tateishi elképzelése mellett, miszerint a technológiát egy jobb világ megteremtésére kell használni, és hogy hozzájárulnak egy jobb társadalomhoz – gyakran úgy, hogy önkéntes és jótékonysági projektekben vesznek részt saját közösségükben. Az innováció mérföldkövei Az OMRON innovációja 1933-ban kezdődött a röntgenfotózáshoz kifejlesztett nagy pontosságú időzítővel. Ez jelentette a vállalat első hozzájárulását a társadalmi igények kielégítéséhez. 1960-ban az OMRON bemutatta a világ első érintkezőmentes közelítéskapcsolóját, amely forradalmasította a fejlett tömeggyártási képességeket. Azóta az OMRON továbbra is úttörő technológiákat vezet be, beleértve a világ első teljesen automatikus jelzőlámpáját, az első teljesen automatizált vasútállomási rendszert, a hordható vérnyomásszabályozót, az ultra nagysebességű fuzzy logikai vezérlőt és az automatikus ráksejt-diagnosztikai berendezéseket.

A robotrendszerek mesterséges intelligenciája (AI) képes kezelni a funkcionális biztonsági elemeket?

2023. április 13. Szerzők: Josep Plassa, az OMRON Europe biztonságtechnikai termékek marketingmenedzsere és Atsushi Oshiro az OMRON Fejlesztési Központjának vezetőjeA robotok és az AI-rendszerek az ipari gyártóüzemek szerves részévé váltak. A robotok használata során a munkavállalók biztonságának érdekében részletes kockázatértékelésre van szükség. Ez az értékelés a funkcionális biztonság szempontjából történik, amely a robotok által végzett autonóm vezérlési műveletek során alkalmazott öt fő elemet vizsgálja: környezetfelismerés, tevékenységtervezés, pályatervezés, mozgásvezérlés és mérés.

Mesterséges intelligencia: ne nevezz butának

2023. február 8. Tíz évvel ezelőtt nagyon büszke voltam arra, hogy a gyárunkban mennyire intelligens gépek vannak. Most, az intelligens szó jelenlegi definícióját ismerve már tudom, hogy az akkori gépek valójában nagyon butának számítanak.Miért? Mert bár azt csinálták, amire tervezték őket, de abban a pillanatban, amint valami váratlan vagy szokatlan dologgal találkoztak, elakadtak. A gépkezelőnek tették fel a kérdést, hogy „mi a baj velem?”.A hibaelhárításhoz és a gépek újbóli üzembe helyezéséhez okos emberekre volt szükség. Magasan képzett gépkezelőkre. Tapasztalt szoftver- és hardvermérnökökre. A probléma az, hogy az elmúlt tíz év során az ilyen szakemberből egyre kevesebb maradt. Egyszerűen nincs elég új tehetség, aki ezt a szakterületet választaná, és ellensúlyozná a nyugdíjkorhatárt elérő munkavállalók számát. Amikor a munkavállalók nyugdíjasként elhagyják a szakmát, magukkal viszik a nehezen megszerzett szaktudásukat, amelynek alapját az évek során szerzett tapasztalatok szolgáltatták. A vállalatok minden egyes távozó munkavállalóval veszítenek hatékonyságukból, hisz kevesebb képzett munkavállalójuk marad.

Út a nettó zéró kibocsátásig: beszéljünk róla!

2023. február 1. Ahhoz, hogy a jövőben elérjük a nettó zéró kibocsátást a gyártás területén, kulcsfontosságú az értéklánc automatizálás által történő átalakítása.2022 júniusában a New Scientist arról számolt be, hogy a világ legnagyobb vállalatainak egyharmada kitűzte céljául a nettó zéró kibocsátás elérését – ami jelentősen nagyobb arány, mint egy évvel korábban.Bár jó hír, hogy egyre nagyobb lelkesedés övezi a témát, a vállalatok nettó zéró kibocsátás elérésére vonatkozó terve a cikk szerint nem elég részletes.Ez valójában nem meglepő. A nettó zéró kibocsátás elérésére vonatkozó stratégia kidolgozása és végrehajtása hatalmas vállalkozás minden vállalat számára, különösen, ha az üvegházhatásúgáz-kibocsátás 80%-a a 3. alkalmazási körbe esik – azaz az értéklánc felsőbb és alsóbb szintjein keletkező kibocsátások körébe. Ez különösen nagy kihívást jelent a napi fogyasztási cikkekkel foglalkozó (FMCG) vállalatok számára, amelyek ellátási láncai és további logisztikai folyamatai hosszúak és összetettek.A legtöbb ilyen vállalkozás tudja, hogy mi a teendő: a szén-dioxid-kibocsátás csökkentése, és körforgás megvalósítása az értékláncban. Erre vonatkozó stratégiájuk is van, amely általában a következőket célozza: az erőforrások és az energia felhasználásának optimalizálása, a nagy kibocsátású termékek és folyamatok lecserélése, valamint a hulladékkeletkezés kiküszöbölése.A legnagyobb kihívás azonban a tervek valóra váltásában rejlik, amiben az automatizálásnak kulcsfontosságú szerepe van.Az adatgyűjtés és -elemzés a nettó zéró kibocsátásra való sikeres átállás kulcsa. Enélkül honnan tudnák a vállalatok, hogy honnan indultak, miben kell fejlődniük, fejlődtek-e, és ha igen, mennyit? A megbízható adatok szolgálnak az elvállalt kötelezettségek teljesítésének, az érdekelt felekkel való hiteles és magabiztos kommunikációnak, valamint az éghajlat-politikai célok megvalósításának alapjául.

Az energia- és üzemanyagválság átvészelése automatizálással

2022. december 7. Az emelkedő árak ellensúlyozása és a környezetvédelmi célok teljesítése érdekében az ipari vállalkozásoknak meg kell vizsgálniuk, hogy az egy forrásból származó automatizálási technológiák hogyan járulhatnak hozzá fenntarthatósági stratégiájukhoz.A magas energia- és üzemanyagárak mind a háztartásokat, mind az ipart megterhelik. A helyzet nem csak a pénzügyi tervekre és a pénztárcákra van negatív hatással, de a rendkívüli drágulás miatt egyes vállalatok kénytelenek leállítani a termelést. A Make UK felmérése szerint a megkérdezett gyártók 42%-a mondta azt, hogy az elmúlt 12 hónapban 100%-kal nőttek a villanyszámlái, 32%-uk pedig azt, hogy a gázárak több mint 100%-kal emelkedtek az elmúlt évben. A gyártók aggasztó 12%-a már létszámcsökkentést hajtott végre a megnövekedett energiaszámlák közvetlen következményeként.Az ukrajnai háború, a Covid-19 világjárvány és a gázárak növekedése csak néhány a válság okai közül, amely minden ágazatot érint, és az energiaáraktól az ellátási láncokig mindenre hatással van. De mit kell most figyelembe venniük a gyártóvállalatoknak? Az átfogó automatizálási stratégiák elengedhetetlenek a nagyobb rugalmasság és az energiahatékonyság érdekében. Ez magában foglalja az innovatív robotikát érzékelő- és képalkotó technológiával párosítva, valamint a mesterséges intelligenciát – a termelés szintjén. Emellett a gyártóüzemek valós idejű adatai segíthetnek a rendellenességek felderítésében és a berendezések általános hatékonyságának (OEE) javításában.

Merre tart az intralogisztika jövője? Ötletek a nagyobb hatékonyságért

2022. november 15. Néha annyira a teljes képre összpontosítunk, hogy elfelejtjük a kisebb, mégis rendkívül fontos folyamatokat, amelyek az intelligens termelést jellemzik. Ilyen például az intralogisztika, azaz az anyag- és áruforgalom, amely egy vállalat telephelyén vagy egy gyártócsarnokban zajlik. Egy nemrégiben készült tanulmány szerint a megkérdezett vállalatok több mint 80 százaléka úgy véli, hogy az intralogisztikában az AI (Mesterséges Intelligencia) és az automatizálás fokozott alkalmazása szükséges az olyan kihívások megoldásához, mint a szakképzett munkaerő hiánya vagy a növekedési tervek.Azoknak az autóipari vállalatoknak, amelyek meg akarnak felelni a piaci és fogyasztói igényeknek, növelni akarják a hatékonyságot és fenntarthatóbbá akarnak válni, új ötletekkel kell előállniuk. Az energiaköltségek, a gázválság és a növekvő infláció még nehezebbé teszik ezt a feladatot. Az innovatív automatizálást, a digitalizációt és az intelligens intralogisztikai megközelítéseket ötvöző intelligens gyárkoncepciók értékes segítséget nyújthatnak. Egyesek ebben az összefüggésben az Ipar 4.0-ról, mások a „jövő gyáráról” beszélnek, megint mások az ipari dolgok internete elnevezést (IIoT) részesítik előnyben. De mindegy, hogy melyik kifejezést választja: A legfontosabb, hogy már most aktívvá váljon, és megbízható partnerekre támaszkodjon. Az intralogisztika jó kiindulópont ha gyors változásokat szeretne elérni. Mert sürgősen cselekedni kell: jelenleg számos vállalatot korlátoz a szakképzett munkaerő hiánya. A modern technológiák, például a mobilrobotok orvosolhatják a helyzetet.

Hogyan járulhat hozzá az adaptív AI vizsgálat a rugalmas gyártáshoz

2022. október 4. A fogyasztók manapság személyre szabott termékekre vágynak, amelyek megfelelnek személyes igényeiknek és ízlésüknek. Ahelyett, hogy „polcra gyártott” és „raktárba küldött” termékeket gyártanának, a gyártóknak személyre szabott, „nekem készült” és „nekem küldött” termékeket kell készíteniük. Ez a hozzáállás forradalmasítja a gyártást, és arra kényszeríti a vállalatokat, hogy újragondolják folyamataikat. Ugyanakkor a panaszmentesség és a selejt nélküli termelés biztosítása is elengedhetetlen.Egy tapasztalt ellenőr gyakorlott szeme gyorsan észreveszi a hibákat, de egy ilyen rutinfeladat fárasztó, és nem lehet a gyártás minden egyes lépésénél elvégezni, különösen a jelenlegi, számos iparágban tapasztalható munkaerőhiány miatt. De lehetne-e automatizálni ezt a feladatot egy változatos, kis volumenű gyártásban is? Egy intelligens képfeldolgozó rendszer vagy egy „elektronikus szem” képes-e utánozni az emberi szem megkülönböztető képességét, és az ismételhetőség és a tartósság előnyeivel ötvözni azt? A legújabb, mesterséges intelligenciával támogatott adaptív ellenőrzés képes leküzdeni az automatizált minőségellenőrzés kihívásait, nagyobb rugalmasság, termelékenység és alkalmazkodóképesség mellett.

Egyedi gépek: moduláris tervezés integrált környezetben

2025. szeptember 2. Napjaink felgyorsult ipari környezetében egyre nagyobb az igény az egyedi gépek iránt. A gépgyártóknak szembe kell nézniük azzal a kihívással, hogy egyedi gépeket állítsanak elő az ügyfelek speciális igényeire szabva. A számos variáció miatt ez a fejlesztés, az üzembe helyezés és a karbantartás hatékonyságának csökkenéséhez vezet. Az OMRON integrált fejlesztési környezetét (Integrated Development Environment – IDE) biztosító Sysmac Studio olyan megoldást kínál, amely leegyszerűsíti a gépfejlesztési folyamatot. Olyan környezetet, amely serkenti a programozók kreativitását és teljes potenciálját.

A manuálisan végrehajtott funkcionális biztonsági ellenőrzésektől az irányított tesztelésig: a biztonsági ellenőrzés korszerűsítése

2025. május 6. A funkcionális biztonság minden ipari automatizálási rendszer esetében alapvető fontosságú. A vészleállító gomboktól kezdve a reteszeken át a fényfüggönyökig a biztonsági alkatrészek és a biztonsági lánc feladata az emberek védelme, valamint a gép integritásának és a szabályozásoknak való megfelelés biztosítása. Annak ellenőrzése azonban, hogy ezek a rendszerek megfelelően működnek-e – különösen a gépek üzembe helyezése és a teljes élettartamuk során történő karbantartása során – továbbra is összetett és időigényes feladat marad, amely sok gyárban magas költségekkel jár.

Észrevehetetlen innováció: digitális vízjelek + ipari automatizálás

2025. március 20. A modern gyártásban a termékek pontosságának, minőségének és fenntarthatóságának biztosítása fontosabb, mint valaha. A rendkívül hatékony, ugyanakkor az emberi szem számára észrevehetetlen digitális vízjelek ígéretes technológiát jelentenek, különösen ipari automatizálási megoldásokkal kombinálva. Fokozzák a nyomonkövethetőséget, és megoldást kínálnak a hagyományos kódok, például a QR- és a DataMatrix-kódok bizonyos korlátaira. Bemutatjuk, hogyan alakítja át ez a technológia a gyártást.

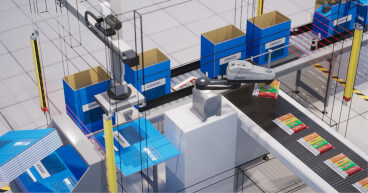

Intelligensebb, gyorsabb és egyszerűbb többrobotos csomagolósorokat szeretne létrehozni?

2025. január 16. Úgy érzi, hogy a robotika integrálása a csomagolósorba olyan, mintha egy rengeteg darabból álló kirakót kellene összeraknia? A nagy teljesítményű, több robotból álló csomagolósorok tervezése gyakran összetett integrációkkal, precíz mozgásvezérléssel és szigorú gyártási igények kielégítésével jár együtt. Akár rendszerintegrátorként egyedi ügyféligényekre szabott megoldásokon dolgozik, akár OEM vállalatként skálázható, szabványosított rendszerek fejlesztésével foglalkozik, az OMRON Robot csomagolástechnikai szoftverkönyvtára olyan eszközöket kínál, amelyekkel leegyszerűsítheti az integrációt és csökkentheti a mérnöki munkával töltött időt. A Robot csomagolástechnikai szoftverkönyvtár segít növelni a teljesítményt és csökkenteni a csomagolási műveletek automatizálásának összetettségét.

Dinamikus gyártósor melletti anyagfeltöltés: válasz napjaink gyártási kihívásaira.

2024. július 15. Itt az ideje, hogy újragondoljuk a gyártósor melletti anyagfeltöltési rendszereket és gyakorlatokat, ha a gyártók hatékonyak és versenyképesek szeretnének maradni, miközben megbirkóznak a testreszabott gyártással és a munkaerőhiánnyal járó kihívásokkal. Lehetséges, hogy erre az AMR-ek és a kobotok jelentik a megoldást? A testreszabási trend számos működési kihívást állított a gyártók elé. A különféle alkatrészek és anyagok használatának igénye változékonysággal jár, amelyet a hagyományos rendszerek nehezen tudnak hatékonyan kezelni. Ez magasabb raktározási költségekhez, hosszabb átfutási időkhöz, valamint gyártási késedelmekhez vezethet. Empirikus adatok tanúskodnak a testreszabás hatásairól a gyártási folyamatokra: a gyártók hosszabb átfutási időkről, magasabb gyártási költségekről, és több raktárkészlet kezelésének szükségletéről számoltak be. Ezek az adatok rámutatnak a testreszabással járó kézzelfogható kihívásokra, és arra, hogy innovatív megközelítésekre van szükség ennek az összetett problémának a hatékony kezelésére.

Robotikai trendek 2024-ben: Az egyszerű és rugalmas alkalmazás elengedhetetlen a teljes potenciál eléréséhez

2024. július 3. A teherhordótól a kollégán át a csapatjátékosig: A robotok szerepe az elmúlt hét évtizedben drámaian megváltozott. A mesterséges intelligencia több lehetőséget teremt, de az ember továbbra is meghatározó tényező marad. Robotok vagy emberek – melyikük fogja meghatározni a termelést a jövőben? George Devol programozható robothoz kapcsolódó 1954-es szabadalma óta ez a kérdés napjainkig vitát vált ki. Devol Unimate névre keresztelt robotja forradalmasította az iparágat a veszélyes feladatok biztonságos elvégzésével. Ezzel rávilágított arra, hogy a hangsúly nem a robotok és emberek küzdelmén van, hanem a robotok és az emberek közös munkájának hatékonyságán. Az elmúlt 70 év során az ipari igények a rugalmasságot, a skálázhatóságot, az alkalmazkodóképességet és a fenntarthatóságot helyezik előtérbe. A robotok olyan feladatokat látnak el, amelyek lehetővé teszik az emberek számára, hogy az értékteremtő tevékenységekre összpontosítsanak.

A pontok összekötése: Az adagolási tevékenységek automatizálása a versenyelőny érdekében

2024. június 18. A robotika fejlesztései elősegítik a rugalmas gyártósori adagolási és kezelési rendszerek koncepcióját, amelyek a munkaerőhiány kezelése mellett növelhetik a biztonságot, a termelékenységet és a minőséget. A gyári automatizálás általában a pontokkal kezdődik. Ez alatt azt a nagy jegygyárat értjük, amely összetett és láthatóan értékteremtő feladatokat lát el – legyen szó folyamatos csomagolásról, fröccsöntésről, buborékcsomagolásról, palackozásról, raklapozásról vagy más alapvető gyártási folyamatokról. Az ezeket a pontokat összekötő vonalak – kezelő-, betöltő- és adagolórendszerek – általában inkább utólagos gondolatnak számítanak, olyannyira, hogy ezeket a tevékenységeket gyakran manuálisan végzik. Könnyebbnek és olcsóbbnak tűnhet, ha egy kezelő nyersanyagokat tölt fel a gyártósorra, vagy alkatrészeket adagol a gépekbe, ahelyett, hogy az automatizálásra költene. Ez azonban szűk látókörű szemlélet, amely nem veszi figyelembe az automatizált gyártósormenti adagolás és kezelés számos üzleti előnyét a hatékonyság, a termékminőség, a méretezhetőség, valamint az egészség és biztonság szempontjából. Emellett ez a nézet egyre inkább idejétmúlt, tekintettel a jelenlegi munkaerő-válság által a gyártási ágazatra gyakorolt nyomásra.

A változó trendek elfogadása: A rugalmas gyártás folyamatának áttekintése

2024. január 30. A gyorsan mozgó fogyasztási cikkek piaca (FMCG) átalakulóban van, amelyet olyan tényezők vezérelnek, mint a fogyasztók előtérbe helyezése, a testreszabási igények, az egészségtudatos preferenciák, a vegán életmód, az etikai aggályok és a fenntarthatóság. Várakozásaink szerint ez a szegmens következő évtizedben több változáson fog keresztülmenni, mint az előző 50 évben. Ez szükségessé teszi a termelés és az ellátási láncok kiigazítását, hogy megfeleljenek a ki- és alakuló trendeknek. A gyorsan mozgó fogyasztási cikkeket előállító gyárak jövője valószínűleg kisebb, intelligensebb létesítményeket jelent majd, autonóm árumozgatással és több egymással összekapcsolt rendszerrel.A termelő berendezéseknek – akár önállóan, akár egymással összekapcsolva – minden eddiginél rugalmasabbnak kell lenniük, hogy időben biztosítani tudják a megfelelő anyagok és csomagolások beérkezését. A gyártásnak rugalmasabbnak kell lennie, és egyre inkább kiskereskedelmi forgalomra kész, kis mennyiségű, változatos termékeket kell előállítania, visszahívásmentes, hibátlan előállítással. A kérdés az, hogyan lehet ezt minimális költséggel és gyors megtérüléssel megvalósítani?

Mi várható az automatizálás terén 2024-ben? Az OMRON Europe hat, a műszaki változásokat előrevetítő irányvonalainak előrejelzése

2023. december 13. Az elmúlt néhány évben bekövetkezett megrázkódtatások sorozata a fokozott geopolitikai és gazdasági kockázatok új korszakát hozta el. Ez arra készteti a gyártókat, hogy az üzleti modelljeiket alkalmazkodóbbá és rugalmasabbá tegyék, és újragondolják a globális ellátási láncaikat és üzleti kapcsolataikat. Ezzel egyidejűleg egyre nagyobb a nyomás, hogy az ESG (Environmental, Social, Governance) környezeti, szociális és vállalatirányítási elveket beépítsék az operatív döntéshozatalba. A mesterséges intelligencia, az adattudomány, a gyártás digitális leképezése (digital twins) valamint az érzékelő, megfigyelő és képalkotó technológiák mind-mind alapvető fontosságúak lesznek az automatizálási és vezérlési megoldások kifejlesztéséhez, amelyek segíthetnek a gyártóiparnak alkalmazkodni ehhez az új valósághoz. Ebben az összefüggésben szeretném megosztani a hat legfontosabb trendet, amelyek 2024-ben és azon túl is hatással lesznek az ipari automatizálásra és alakítani is fogják majd azt.

A munkaerőhiány-kezelés négy legjobb módja az automatizálás segítségével

2023. szeptember 6. Automatizálással nem felváltani, hanem támogatni lehet a kétkezi munkát végző munkaerőt.A gyártási folyamatokat sújtó munkaerőhiány világszerte egyre nagyobb aggodalomra ad okot. Az ellensúlyozásnak szánt pénzügyi ösztönzőkön és célzott munkaerő-képesítéseken túl innovatívabb megoldásokra van szükség. Sok gyártó dönt úgy, hogy automatizálja az ismétlődő tevékenységeket; de vajon támogatja ez a lépés az érintett dolgozókat, vagy teljesen elveszi előlük a munkát?2023-ban a Reuters felmérése riasztó tendenciát mutatott: a megkérdezett vállalatok rekordmagas arányban 53%-uk jelezte, hogy munkaerő-felvételi nehézségekkel küzd. A munkaerőhiány, az elszabaduló energiaköltségek, valamint a klímasemlegességre való törekvés új kihívásokat teremt. A fenntartható gyártás érdekében a fejlődés irányát a munkaerőhiány kezelésére és a meglévő erőforrások gondozására irányuló innovatív stratégiák jelentik.Lássuk, mi is a munkaerőhiány kezelésének és a meglévő munkaerő automatizálással történő segítésének négy legjobb módja:

Az OMRON Europe 5 legfontosabb automatizálási előrejelzése 2023-ra

2023. február 1. Az új év előttünk áll, annak minden lehetőségével együtt, ezért szeretnék kiemelni néhányat a legfontosabb trendek közül, amelyek hatással lesznek az ipari automatizálásra 2023-ban és azon túl. A feldolgozóipar továbbra is számos kihívással fog szembenézni, és ezek leküzdése az üzleti modellek alkalmazkodó képességének és rugalmasságának megteremtésével jár majd. Ugyanakkor a vállalatoknak el kell fogadniuk a feltörekvő technológiákat – érzékelési megoldások, robotika, 5G és mesterséges intelligencia – hogy segítsenek megoldani a társadalmi kihívások miatt felmerülő problémákat.

„Riders of the storm”: a gazdasági bizonytalanság leküzdése a társadalmi kihívások technológiai lehetőségekké alakításával

2022. december 6. Az egyik kérdés, amit gyakran feltesznek nekem, az az, hogy mint ipari automatizálási vállalkozás, mi a stratégiánk a stabil növekedés fenntartására egy változékony és egyre kiszámíthatatlanabb globális gazdaságban. A válaszom, ahogy azt önök is gondolhatják, nem egy mondatból áll, habár egy fogalomban gyökerezik: SINIC. A SINIC a „Seed-Innovation to Need-Impetus Cyclic Evolution (Az innováció alapjaitól a szükséglet-vezérelt evolúciós körforgásig)” rövidítése, amely egy az OMRON alapítója, Dr. Kazuma Tateisi által 1970-ben kidolgozott elmélet. E filozófia szerint a tudomány, a technológia és a társadalom ciklikus kapcsolatban állnak, kölcsönösen befolyásolják és alakítják egymást. A tudományos áttörések segítik a társadalom fejlődését, a társadalmi igények pedig ösztönzik a technológiai fejlődést. Az OMRON Europe mindig is ezt a filozófiát követte, és az elmúlt évtizedet azzal töltötte, hogy megalapozta az értékteremtő megoldásokat a mai társadalmi és gazdasági kihívásokra.

Őrizze meg biztonságát, és feleljen meg a szabályozásoknak: Az öt legfontosabb tipp az EU gépekről szóló rendeletére való felkészüléshez

2025. december 2. A kibertámadások valódi fenyegetést jelentenek a gyártási ágazatban, ahol megzavarhatják a termelést, károsíthatják a gépeket, és végső soron veszélybe sodorhatják a vállalkozásokat. Az Európai Unió új, gépekről szóló rendeletének (2023/1230/EU) célja – amely 2027 januárjában váltja fel a 2006/42/EK gépekről szóló irányelvet –, hogy segítse a gépek védelmét ezekkel a kockázatokkal szemben. A rendelet betartása az EU teljes területén kötelező. A gépgyártók számára ez azt jelenti, hogy a védelmet már a tervezés során be kell építeni. A végfelhasználók számára ez azt jelenti, hogy a berendezéseket nagy fokú éberséggel kell üzemeltetni és karbantartani. Íme öt fontos tipp, amelyek mindkét fél számára hasznosak lehetnek a jövőbeli követelmények teljesítéséhez és a fenyegetések kivédéséhez.

Az IT/OT közötti rés áthidalása: Gyakorlati lépések egy összekapcsolt jövő felé

2025. november 17. Napjaink ipari párbeszédét a mesterséges intelligencia, az adatgyűjtés, a digitális leképezések és az IT/OT konvergencia dominálják. Sok gyártó számára azonban egy kihívás továbbra is megoldatlan: a munkát megtervező vállalati rendszerek és a megvalósítást biztosító operatív technológiák közötti szakadék áthidalása. Az ERP-rendszerek és a MES-platformok továbbra is az egyik oldalon, míg a PLC-k, az érzékelők és a robotok a másik oldalon helyezkednek el. Az informatika (IT) és az operatív technológia (OT) évtizedek óta inkább párhuzamosan, mintsem együttesen fejlődtek. Az IT biztosítja az adatokat, az elemzéseket és a vállalati átláthatóságot; az OT pedig a gépek üzemeltetését, a gépbiztonságot, és a gyártás megbízhatóságát. Mindkettő elengedhetetlen, de gyakran a vállalati szinten generált adatok nem jutnak vissza a gyártórészleghez, míg az értékes működési adatok is a mérnöki csapatok körében maradnak meg. Ennek eredményeként a digitális átalakulás teljes ígérete elérhetetlen marad. Ez a szakadék már nem csupán technikai, hanem stratégiai. A gyártók folyamatos nyomással szembesülnek, hogy gyorsabban alkalmazkodjanak a változó kereslethez, a rövidebb innovációs ciklusokhoz és a növekvő fenntarthatósági elvárásokhoz. Ezek a célok nem érhetőek el, ha a digitális és fizikai rendszerek továbbra is egymástól elszigetelten működnek. Egyes automatizálási beszállítók már megkezdték az IT- és OT-megoldások együttes fejlesztését, de a valódi versenyképesség ma már az iparágak legjobb szakértőit összefogó együttműködésen és a közös alkotáson múlik. Hogyan tudnak tehát a gyártók a koncepciótól eljutni a megvalósításig? Az OMRON tapasztalatai és az iparágak közötti együttműködéseink alapján négy gyakorlati módszert mutatunk be az IT/OT konvergencia felgyorsítására.

Virtuális üzembe helyezés: A költségek csökkentése és a géphitelesítés javítása

2025. október 1. „Nem beszéltünk róla, mert azt hittem, hogy tudod” – egy olyan mondat, amit az évek során sokat hallottam. A nem megfelelő kommunikáció az első számú oka annak, hogy az ipari automatizálási projektek az üzembe helyezés szakaszában nem mennek a terv szerint. Legyen szó új gépről, új celláról vagy egy teljes gyártósorról, gyakran félreértések merülnek fel a projektpartnerek között a terv kivitelezésével kapcsolatban. A dokumentációval kapcsolatos konzultáció nem mindig segít, mert gyakran a pontatlan, nem egyértelmű vagy hiányos információk okozzák a nézeteltérést. Jó példa erre a bemenetek, kimenetek és interfészek közötti hibás kommunikáció. A rendszerintegrátor feltételezheti, hogy egy berendezés EtherCAT-et használ, míg a gyártó a Profinetet várná el. Vagy talán egy gyártósor-integrátor elfelejt megemlíteni egy érzékelőt, amely a gép biztonsága szempontjából fontos kiegészítő információkat rögzít. Mindkét esetben ugyanaz az eredmény: többletköltségek, elvesztegetett idő és növekvő frusztráció minden érintett fél számára. A megoldás egyszerű: ne hagyja, hogy az emberek egyedül hozzák létre a specifikációkat. A virtuális üzembe helyezés sokkal pontosabb specifikációkat eredményez.

5 adatterület, amelyet már most is nyomon kellene követnie a gyártósorain

2025. szeptember 5. Valószínűleg hallotta már a „digitális átalakulás”, az „intelligens gyár” és az „adatvezérelt döntéshozatal” kifejezéseket, és a felénél már valószínűleg elvesztette a fonalat. Ez a legtöbbünk számára egy rendkívül új világ. Azonban a gyártóipar komoly szereplői, akik megőrzik versenyképességüket, teljesítik az üzemidőcélokat és megőrzik a haszonkulcsukat, néhány kulcsfontosságú adatot pontosan nyomon követnek. Nem az összeset, csak azokat, amelyek számítanak. Ha Ön ezeket nem kíséri figyelemmel, akkor valószínűleg túl sokat költ, túl sok a vesztesége, vagy csak vakon cselekszik. Stefan Jensennel, az OptiPeople vezérigazgatójával, egy olyan vállalat vezetőjével beszélgettünk, amely mélyen beleásta magát a termelési adatok világába, és öt alapvető kategóriába sorolta az adatokon alapuló termelést. Mindegyik elég egyszerű, de ha nem cselekszik, akkor a legközelebbi versenytársai le fogják hagyni.

Hogyan építsünk rugalmasságot minden gyártási döntésbe?

2025. július 17. Gyarapodás a kihívásokon keresztül: Hogyan építsünk rugalmasságot minden gyártási döntésbe?A mai világban az alkalmazkodóképesség már nem csupán versenyelőny, hanem szükségszerűség. A különböző ágazatokban a gyártók folyamatos zavarokkal küzdenek: változó jogszabályok, kiszámíthatatlan kereslet, változó ellátási láncok, növekvő munkaerőhiány és képzettségi különbségek. A rugalmasság nem lehet másodlagos szempont. Be kell építeni a rendszerbe, be kell ágyazni a stratégiába, valamint technológiai és kulturális eszközökkel kell megerősíteni.Az alábbiakban bemutatunk öt alapelvet, amelyek segítségével a rugalmasság beépíthető a gyártási folyamatokba:1. Az ügyfelek és a partnerek előtérbe helyezéseA rugalmas gyártóknak egy közös vonásuk van: a hosszú távú kapcsolatokat helyezik előtérbe. Tapasztalataink szerint az ügyfelekkel és a technológiai szolgáltatókkal kialakított szoros partnerségek olyan bizalmi alapot teremtenek, amely zavarok esetén felbecsülhetetlen értékűvé válik. Ez az alap idővel egyre szilárdabbá és erősebbé válik. Akár globális alkatrészhiányról, akár hirtelen szabályozási változásról van szó, a nyitottsággal, lojalitással és együttműködéssel működő vállalatok gyorsabban és hatékonyabban reagálnak. Ezek az emberi kapcsolatok ugyanolyan fontosak a rugalmaság szempontjából, mint bármely gép vagy rendszer.

Szimuláció: a koncepciótól a virtuális másolatig

2025. június 4. Hogyan használhatják ki a gyártók a szimuláció erejét annak érdekében, hogy a való világbeli tervezést már az első alkalommal helyesen valósítsák meg? Maga a koncepció, hogy szimulációt használjanak a gyárak tervezéséhez, már évek óta létezik, sőt, még a számítógépek előtt is létezett. A szimuláció legkorábbi példái kézzelfogható modellek voltak, amelyek lehetővé tették a mérnökök számára, hogy kisebb méretben teszteljék a folyamatokat és a terveket, mielőtt élesben alkalmazták volna azokat. Bár ugyanazok az alapelvek még mindig érvényesek, manapság a szimuláció virtuális környezetben zajlik. Ez sokkal nagyobb kapacitást biztosít arra, hogy összetett folyamatokat hozzanak létre annak érdekében, hogy teszteljék, miképp befolyásolják a változó tényezők az eredményeket. Az AI-alapú technológiák nagyban hozzájárultak a rugalmasság és a kifinomultság ezen szintjének eléréséhez.

Termék- és folyamattervezés – digitálisan

2025. április 10. A forgatókönyv a következő: Ön egy gyártó, aki egy új terméket szeretne kifejleszteni, és a gyártáshoz egy új gyártósorba kell beruháznia. Olvasott a digitalizáció előnyeiről, és szívesen alkalmazna egy high-tech megközelítést. Hol kezdje?Ha új terméket fejleszt, és új gyártósorra van szüksége, az első alapelv az, hogy a terméktervezés határozza meg a folyamattervezést, és nem fordítva. A második, hogy mindkettő párhuzamosan történik, ami egy digitális gyárban csökkenti a piacra kerülési időt.

Intelligensebb, gyorsabb és egyszerűbb többrobotos csomagolósorokat szeretne létrehozni?

2025. január 16. Úgy érzi, hogy a robotika integrálása a csomagolósorba olyan, mintha egy rengeteg darabból álló kirakót kellene összeraknia? A nagy teljesítményű, több robotból álló csomagolósorok tervezése gyakran összetett integrációkkal, precíz mozgásvezérléssel és szigorú gyártási igények kielégítésével jár együtt. Akár rendszerintegrátorként egyedi ügyféligényekre szabott megoldásokon dolgozik, akár OEM vállalatként skálázható, szabványosított rendszerek fejlesztésével foglalkozik, az OMRON Robot csomagolástechnikai szoftverkönyvtára olyan eszközöket kínál, amelyekkel leegyszerűsítheti az integrációt és csökkentheti a mérnöki munkával töltött időt. A Robot csomagolástechnikai szoftverkönyvtár segít növelni a teljesítményt és csökkenteni a csomagolási műveletek automatizálásának összetettségét.

Eligazodás a berendezésekről szóló új szabályozásban

2025. január 16. Az Európai Unió 2027. január 20-tól a berendezésekről szóló 2006/42/EK irányelvről áttér az új, berendezésekről szóló rendeletre (2023/1230/EU), amely jelentős változást jelent a berendezésekre és a kapcsolódó termékekre vonatkozó jogszabályi követelmények terén. A rendszerintegrátorok számára a rendelet szigorúbb követelményeket vezet be az AI-vezérelt rendszerek, az autonóm berendezések és az összekapcsolt berendezések beépítésére vonatkozóan. A végfelhasználók, különösen az összetett géprendszereket működtető felhasználók számára stratégiai fontosságú az ezekre a változásokra való felkészülés.

Az optimalizálástól az autonómiáig – A 2025-ös év öt legfontosabb gyártásautomatizálási trendje

2025. január 4. Ahogy belépünk 2025-be, az ipari automatizálás világa új fejezethez közeledik. Az OMRON SINIC-elmélete szerint, amely a technológia fejlődést a társadalmi változáshoz köti, az optimalizáló társadalom felől elmozdulunk az autonóm társadalom felé. Az OMRON alapítója, Kazuma Tateishi által 1970-ben megalkotott elmélet alapján a jövőbeli társadalmi és technológiai fejlődések fognak irányt mutatni az innovációnak. A működés javítása érdekében az optimalizálási fázisban a hangsúly a folyamatok finomítására, a hatékonyság növelésére és a technológia felhasználására helyeződött. Az autonóm társadalom azonban egy teljesen új korszak – egy olyan, amelyben a rendszerek nem csak hatékonyan működnek, hanem önszabályozóvá, öntanulóvá és önálló döntéshozatalra képessé válnak.

Az akkumulátor alapú jövő biztosítása automatizált újrafeldolgozással

2024. december 17. Ahogy a COP 28 konferencián kitűzött célok elérése érdekében a fosszilis tüzelőanyagoktól való függőséget magunk mögött hagyva egyre inkább áttérünk a tisztább energiatechnológiákra, az akkumulátorok döntő szerephez jutnak a megújuló energiaforrások arányának növelésében, mind az energiamix, mind a közlekedés villamosításának terén.Ez a folyamat jelentősen megnövelte az akkumulátorpiacon jelentkező keresletet, különösen két szektorban: az energiaiparban és a közlekedésben. A Nemzetközi Energiaügynökség (International Energy Agency, IEA) szerint az energiaszektor az akkumulátorok iránti teljes kereslet több mint 90%-áért felelős. Az ügynökség jelentése szerint 2023-ban az energiaszektor akkumulátoros kapacitása éves szinten több mint 130%-kal nőtt, világszerte összesen 42 gigawattal (GW) bővítve az elektromos hálózatokat. Az akkumulátorok esetében az energiatárolás egyre jelentősebb alkalmazási területet jelent, mivel lehetővé teszi a megújuló energiaforrásokból nyert energia tárolását, és várhatóan a jövőben egyre fontosabb szerepet fog játszani. A közlekedési ágazatban ugyanakkor az akkumulátorok elősegítették az elektromos autók, kerékpárok, teherautók, buszok és más akkumulátoros járművek elterjedését.

Első lépések a sikeres digitalizáció felé

2024. november 12. Egy digitális gyár létesítése önmagában nem tekinthető végcélnak. A digitális gyár egy eszköz, amely rugalmasságot biztosít a gyártással foglalkozó vállalkozásoknak, hogy reagálhassanak a piaci változásokra – legyen szó akár az innovációs trendekről vagy a költségnövekedésről, függetlenül attól, hogy az élelmiszer- és italgyártás, a személyes higiénia, a gyógyszeripar vagy éppen az autóipar területén tevékenykednek.

Észrevehetetlen innováció: digitális vízjelek + ipari automatizálás

2025. március 20. A modern gyártásban a termékek pontosságának, minőségének és fenntarthatóságának biztosítása fontosabb, mint valaha. A rendkívül hatékony, ugyanakkor az emberi szem számára észrevehetetlen digitális vízjelek ígéretes technológiát jelentenek, különösen ipari automatizálási megoldásokkal kombinálva. Fokozzák a nyomonkövethetőséget, és megoldást kínálnak a hagyományos kódok, például a QR- és a DataMatrix-kódok bizonyos korlátaira. Bemutatjuk, hogyan alakítja át ez a technológia a gyártást.

Eligazodás a berendezésekről szóló új szabályozásban

2025. január 16. Az Európai Unió 2027. január 20-tól a berendezésekről szóló 2006/42/EK irányelvről áttér az új, berendezésekről szóló rendeletre (2023/1230/EU), amely jelentős változást jelent a berendezésekre és a kapcsolódó termékekre vonatkozó jogszabályi követelmények terén. A rendszerintegrátorok számára a rendelet szigorúbb követelményeket vezet be az AI-vezérelt rendszerek, az autonóm berendezések és az összekapcsolt berendezések beépítésére vonatkozóan. A végfelhasználók, különösen az összetett géprendszereket működtető felhasználók számára stratégiai fontosságú az ezekre a változásokra való felkészülés.

Miért töltenek be kritikus fontosságú szerepet az automatizált ellenőrző rendszerek az elektromos járművek gyártása terén?

2023. március 23. A gépjárműiparban a biztonság minden egyéb aggályt felülmúl, és ez alól az elektromos járművek gyártása sem jelent kivételt. A biztonság ugyanakkor összetettebb folyamatok bevezetésével is járhat, napjaink járműveinek, és különösen az elektromos járműveknek az összetettsége pedig olyan mértékű, hogy a gyártók a továbbiakban már nem támaszkodhatnak a hagyományos mintavételi vagy auditon alapuló ellenőrzési módszerekre.

A Vadain gépi képfeldolgozással automatizálja a függönyszövetek ellenőrzését

2022. április 8. A Vadainnek, az egyedi függönygyártás hollandiai piacvezetőjének egy olyan megoldásra volt szüksége, amellyel a lehető legkorábban észlelhetők a hibák a több kilométer hosszú függönyanyagokon. Ezért a Sycade szoftverfejlesztőivel és az Eisenkolb gépgyártó vállalattal összefogva, valamint az az OMRON gépi képfeldolgozó technológiájára támaszkodva kifejlesztettek egy automatizált megoldást, amellyel észlelhetők és elemezhetők a függönyanyagokon előforduló hibák, így az időigényes kézi szemrevételezési folyamat immár a múlté.

Factory automation: four tips for the future of food & beverage manufacturing

2020. július 16. The coronavirus pandemic has posed major challenges to organisations of all types and sizes. In the food and commodity industry, companies have faced significantly reduced consumption and disrupted supply chains, while at-home consumption increased, and out-of-home consumption came near to a standstill. But how can manufacturers adapt their business strategies and production processes both now and in the longer term? The pandemic may provide an opportunity for rethinking outdated processes and procedures and enhancing them with concepts such as innovative robotics, sensor technology and holistic automation strategies.

Six challenges for brand protection

2019. november 19. Brand protection is an important topic for any business. But as industrial companies invest in new technology, such as smart robotics, artificial intelligence and vision systems, are they aware of the key challenges that could affect their brand?

Legacy of machine vision

2019. október 16. Did you know that for more than 40 years, Omron has developed vision sensing technologies for factory automation, surveillance and transport systems, and more recently for facial recognition and image processing for mobile phones, and even driver monitoring for autonomous driving?

Late-stage customization in pharmaceutical manufacturing

2019. október 16. As a result of serialization legislation, pharmaceutical manufacturers must now ensure that labels printed at a late stage contain all of the data required for compliance. This includes customizing product labels for certain markets, customers or products by adding variable data to labels or packaging. This avoids the need to stock individual packaging materials for each variant.

How to secure FMCG supply chains with traceability?

2019. október 2. The traceability of food and drink products throughout the production and distribution process can be a complex issue. For example, alcoholic drink producers need systems that enable them to comply with local regulations regarding food traceability, as well as tax legislation.

Barcodes: keeping track of product quality

2019. október 2. For many years, barcode technology has proved to be an economical and flexible identification technology. It has continued to develop and as a result, 1D and 2D codes (such as Datamatrix) are now used almost universally. Their versatility have made them a popular choice for streamlining many key supply chain processes, including production, logistics and item traceability.

Az IT/OT közötti rés áthidalása: Gyakorlati lépések egy összekapcsolt jövő felé

2025. november 17. Napjaink ipari párbeszédét a mesterséges intelligencia, az adatgyűjtés, a digitális leképezések és az IT/OT konvergencia dominálják. Sok gyártó számára azonban egy kihívás továbbra is megoldatlan: a munkát megtervező vállalati rendszerek és a megvalósítást biztosító operatív technológiák közötti szakadék áthidalása. Az ERP-rendszerek és a MES-platformok továbbra is az egyik oldalon, míg a PLC-k, az érzékelők és a robotok a másik oldalon helyezkednek el. Az informatika (IT) és az operatív technológia (OT) évtizedek óta inkább párhuzamosan, mintsem együttesen fejlődtek. Az IT biztosítja az adatokat, az elemzéseket és a vállalati átláthatóságot; az OT pedig a gépek üzemeltetését, a gépbiztonságot, és a gyártás megbízhatóságát. Mindkettő elengedhetetlen, de gyakran a vállalati szinten generált adatok nem jutnak vissza a gyártórészleghez, míg az értékes működési adatok is a mérnöki csapatok körében maradnak meg. Ennek eredményeként a digitális átalakulás teljes ígérete elérhetetlen marad. Ez a szakadék már nem csupán technikai, hanem stratégiai. A gyártók folyamatos nyomással szembesülnek, hogy gyorsabban alkalmazkodjanak a változó kereslethez, a rövidebb innovációs ciklusokhoz és a növekvő fenntarthatósági elvárásokhoz. Ezek a célok nem érhetőek el, ha a digitális és fizikai rendszerek továbbra is egymástól elszigetelten működnek. Egyes automatizálási beszállítók már megkezdték az IT- és OT-megoldások együttes fejlesztését, de a valódi versenyképesség ma már az iparágak legjobb szakértőit összefogó együttműködésen és a közös alkotáson múlik. Hogyan tudnak tehát a gyártók a koncepciótól eljutni a megvalósításig? Az OMRON tapasztalatai és az iparágak közötti együttműködéseink alapján négy gyakorlati módszert mutatunk be az IT/OT konvergencia felgyorsítására.

Virtuális üzembe helyezés: A költségek csökkentése és a géphitelesítés javítása

2025. október 1. „Nem beszéltünk róla, mert azt hittem, hogy tudod” – egy olyan mondat, amit az évek során sokat hallottam. A nem megfelelő kommunikáció az első számú oka annak, hogy az ipari automatizálási projektek az üzembe helyezés szakaszában nem mennek a terv szerint. Legyen szó új gépről, új celláról vagy egy teljes gyártósorról, gyakran félreértések merülnek fel a projektpartnerek között a terv kivitelezésével kapcsolatban. A dokumentációval kapcsolatos konzultáció nem mindig segít, mert gyakran a pontatlan, nem egyértelmű vagy hiányos információk okozzák a nézeteltérést. Jó példa erre a bemenetek, kimenetek és interfészek közötti hibás kommunikáció. A rendszerintegrátor feltételezheti, hogy egy berendezés EtherCAT-et használ, míg a gyártó a Profinetet várná el. Vagy talán egy gyártósor-integrátor elfelejt megemlíteni egy érzékelőt, amely a gép biztonsága szempontjából fontos kiegészítő információkat rögzít. Mindkét esetben ugyanaz az eredmény: többletköltségek, elvesztegetett idő és növekvő frusztráció minden érintett fél számára. A megoldás egyszerű: ne hagyja, hogy az emberek egyedül hozzák létre a specifikációkat. A virtuális üzembe helyezés sokkal pontosabb specifikációkat eredményez.

5 adatterület, amelyet már most is nyomon kellene követnie a gyártósorain

2025. szeptember 5. Valószínűleg hallotta már a „digitális átalakulás”, az „intelligens gyár” és az „adatvezérelt döntéshozatal” kifejezéseket, és a felénél már valószínűleg elvesztette a fonalat. Ez a legtöbbünk számára egy rendkívül új világ. Azonban a gyártóipar komoly szereplői, akik megőrzik versenyképességüket, teljesítik az üzemidőcélokat és megőrzik a haszonkulcsukat, néhány kulcsfontosságú adatot pontosan nyomon követnek. Nem az összeset, csak azokat, amelyek számítanak. Ha Ön ezeket nem kíséri figyelemmel, akkor valószínűleg túl sokat költ, túl sok a vesztesége, vagy csak vakon cselekszik. Stefan Jensennel, az OptiPeople vezérigazgatójával, egy olyan vállalat vezetőjével beszélgettünk, amely mélyen beleásta magát a termelési adatok világába, és öt alapvető kategóriába sorolta az adatokon alapuló termelést. Mindegyik elég egyszerű, de ha nem cselekszik, akkor a legközelebbi versenytársai le fogják hagyni.

5 praktikus módszer az intelligensebb, keskenyebb és megbízhatóbb vezérlőpanelek építéséhez

2025. augusztus 5. Ha valaha is belenézett egy ipari gyártósoron lévő gépbe, valószínűleg látott már vezérlőpanelt. Ez az a strukturált tér, ahol tápegységek, relék, csatlakozók és vezérlők kapnak helyet. A vezérlőpanelek létfontosságú elemek, amelyek biztosítják a gépek működését, a folyamatok megvalósulását és a gyártósorok rendeltetésszerű működését. De a modern vezérlőpanelek sokkal többre lehetnek képesek, mint csupán az alkatrészek tárolására. Ha a megfelelő megközelítést alkalmazzuk, hozzájárulnak az építési idő csökkentéséhez, az anyagfelhasználás minimalizálásához, javítják a helykihasználást, és növelik a rendszerek hosszú távú megbízhatóságát.

Hogyan építsünk rugalmasságot minden gyártási döntésbe?

2025. július 17. Gyarapodás a kihívásokon keresztül: Hogyan építsünk rugalmasságot minden gyártási döntésbe?A mai világban az alkalmazkodóképesség már nem csupán versenyelőny, hanem szükségszerűség. A különböző ágazatokban a gyártók folyamatos zavarokkal küzdenek: változó jogszabályok, kiszámíthatatlan kereslet, változó ellátási láncok, növekvő munkaerőhiány és képzettségi különbségek. A rugalmasság nem lehet másodlagos szempont. Be kell építeni a rendszerbe, be kell ágyazni a stratégiába, valamint technológiai és kulturális eszközökkel kell megerősíteni.Az alábbiakban bemutatunk öt alapelvet, amelyek segítségével a rugalmasság beépíthető a gyártási folyamatokba:1. Az ügyfelek és a partnerek előtérbe helyezéseA rugalmas gyártóknak egy közös vonásuk van: a hosszú távú kapcsolatokat helyezik előtérbe. Tapasztalataink szerint az ügyfelekkel és a technológiai szolgáltatókkal kialakított szoros partnerségek olyan bizalmi alapot teremtenek, amely zavarok esetén felbecsülhetetlen értékűvé válik. Ez az alap idővel egyre szilárdabbá és erősebbé válik. Akár globális alkatrészhiányról, akár hirtelen szabályozási változásról van szó, a nyitottsággal, lojalitással és együttműködéssel működő vállalatok gyorsabban és hatékonyabban reagálnak. Ezek az emberi kapcsolatok ugyanolyan fontosak a rugalmaság szempontjából, mint bármely gép vagy rendszer.

Szimuláció: a koncepciótól a virtuális másolatig

2025. június 4. Hogyan használhatják ki a gyártók a szimuláció erejét annak érdekében, hogy a való világbeli tervezést már az első alkalommal helyesen valósítsák meg? Maga a koncepció, hogy szimulációt használjanak a gyárak tervezéséhez, már évek óta létezik, sőt, még a számítógépek előtt is létezett. A szimuláció legkorábbi példái kézzelfogható modellek voltak, amelyek lehetővé tették a mérnökök számára, hogy kisebb méretben teszteljék a folyamatokat és a terveket, mielőtt élesben alkalmazták volna azokat. Bár ugyanazok az alapelvek még mindig érvényesek, manapság a szimuláció virtuális környezetben zajlik. Ez sokkal nagyobb kapacitást biztosít arra, hogy összetett folyamatokat hozzanak létre annak érdekében, hogy teszteljék, miképp befolyásolják a változó tényezők az eredményeket. Az AI-alapú technológiák nagyban hozzájárultak a rugalmasság és a kifinomultság ezen szintjének eléréséhez.

A manuálisan végrehajtott funkcionális biztonsági ellenőrzésektől az irányított tesztelésig: a biztonsági ellenőrzés korszerűsítése

2025. május 6. A funkcionális biztonság minden ipari automatizálási rendszer esetében alapvető fontosságú. A vészleállító gomboktól kezdve a reteszeken át a fényfüggönyökig a biztonsági alkatrészek és a biztonsági lánc feladata az emberek védelme, valamint a gép integritásának és a szabályozásoknak való megfelelés biztosítása. Annak ellenőrzése azonban, hogy ezek a rendszerek megfelelően működnek-e – különösen a gépek üzembe helyezése és a teljes élettartamuk során történő karbantartása során – továbbra is összetett és időigényes feladat marad, amely sok gyárban magas költségekkel jár.

Termék- és folyamattervezés – digitálisan

2025. április 10. A forgatókönyv a következő: Ön egy gyártó, aki egy új terméket szeretne kifejleszteni, és a gyártáshoz egy új gyártósorba kell beruháznia. Olvasott a digitalizáció előnyeiről, és szívesen alkalmazna egy high-tech megközelítést. Hol kezdje?Ha új terméket fejleszt, és új gyártósorra van szüksége, az első alapelv az, hogy a terméktervezés határozza meg a folyamattervezést, és nem fordítva. A második, hogy mindkettő párhuzamosan történik, ami egy digitális gyárban csökkenti a piacra kerülési időt.

Optimising Production: How Smart Maintenance Technologies Are Changing the Game

2025. január 21. Unplanned downtime is sabotaging production goals. It's time to take action.Unexpected machine stoppages aren't just inconveniences—they represent costly disruptions that derail schedules, increase operational expenses, and reduce profitability. Efficiency and reliability are crucial factors for maintaining competitiveness in manufacturing, so, minimising productivity losses such as unplanned downtime must be a strategic priority for both small and medium enterprises (SMEs) and large corporations.But what if you could anticipate equipment failures before they happen, deploy machines designed with maintenance in mind, and minimise fault finding? Smart maintenance technologies are making all of these a reality, transforming operations from reactive firefighting to proactive problem-solving.In this blog, we’ll explore how predictive maintenance, intelligent machine design, and advanced diagnostics are helping manufacturers reduce downtime, optimise costs, and stay ahead in an ever-evolving industry.

Az akkumulátor alapú jövő biztosítása automatizált újrafeldolgozással

2024. december 17. Ahogy a COP 28 konferencián kitűzött célok elérése érdekében a fosszilis tüzelőanyagoktól való függőséget magunk mögött hagyva egyre inkább áttérünk a tisztább energiatechnológiákra, az akkumulátorok döntő szerephez jutnak a megújuló energiaforrások arányának növelésében, mind az energiamix, mind a közlekedés villamosításának terén.Ez a folyamat jelentősen megnövelte az akkumulátorpiacon jelentkező keresletet, különösen két szektorban: az energiaiparban és a közlekedésben. A Nemzetközi Energiaügynökség (International Energy Agency, IEA) szerint az energiaszektor az akkumulátorok iránti teljes kereslet több mint 90%-áért felelős. Az ügynökség jelentése szerint 2023-ban az energiaszektor akkumulátoros kapacitása éves szinten több mint 130%-kal nőtt, világszerte összesen 42 gigawattal (GW) bővítve az elektromos hálózatokat. Az akkumulátorok esetében az energiatárolás egyre jelentősebb alkalmazási területet jelent, mivel lehetővé teszi a megújuló energiaforrásokból nyert energia tárolását, és várhatóan a jövőben egyre fontosabb szerepet fog játszani. A közlekedési ágazatban ugyanakkor az akkumulátorok elősegítették az elektromos autók, kerékpárok, teherautók, buszok és más akkumulátoros járművek elterjedését.

Túl az öncélú technológián: Az ipari automatizálás és a tökéletes működés találkozása

2024. november 30. Az elmúlt néhány évben gyors technológiai fejlődésnek lehettünk tanúi, amelynek egyik legfontosabb jelensége az MI előretörése volt. Az Egyesült Királyságban, az Egyesült Államokban és a Kanadában működő gyártók körében végzett felmérés során a megkérdezettek 70%-a nyilatkozott úgy, hogy az MI valamilyen formáját már alkalmazzák működésük során. Ez a hajlandóság az új technológiák bevezetésére figyelemre méltó, különösen azért, mert a gyártási ágazat számára rengeteg lehetőség rejlik az automatizálásban.

Első lépések a sikeres digitalizáció felé

2024. november 12. Egy digitális gyár létesítése önmagában nem tekinthető végcélnak. A digitális gyár egy eszköz, amely rugalmasságot biztosít a gyártással foglalkozó vállalkozásoknak, hogy reagálhassanak a piaci változásokra – legyen szó akár az innovációs trendekről vagy a költségnövekedésről, függetlenül attól, hogy az élelmiszer- és italgyártás, a személyes higiénia, a gyógyszeripar vagy éppen az autóipar területén tevékenykednek.

Hogyan építsünk rugalmasságot minden gyártási döntésbe?

2025. július 17. Gyarapodás a kihívásokon keresztül: Hogyan építsünk rugalmasságot minden gyártási döntésbe?A mai világban az alkalmazkodóképesség már nem csupán versenyelőny, hanem szükségszerűség. A különböző ágazatokban a gyártók folyamatos zavarokkal küzdenek: változó jogszabályok, kiszámíthatatlan kereslet, változó ellátási láncok, növekvő munkaerőhiány és képzettségi különbségek. A rugalmasság nem lehet másodlagos szempont. Be kell építeni a rendszerbe, be kell ágyazni a stratégiába, valamint technológiai és kulturális eszközökkel kell megerősíteni.Az alábbiakban bemutatunk öt alapelvet, amelyek segítségével a rugalmasság beépíthető a gyártási folyamatokba:1. Az ügyfelek és a partnerek előtérbe helyezéseA rugalmas gyártóknak egy közös vonásuk van: a hosszú távú kapcsolatokat helyezik előtérbe. Tapasztalataink szerint az ügyfelekkel és a technológiai szolgáltatókkal kialakított szoros partnerségek olyan bizalmi alapot teremtenek, amely zavarok esetén felbecsülhetetlen értékűvé válik. Ez az alap idővel egyre szilárdabbá és erősebbé válik. Akár globális alkatrészhiányról, akár hirtelen szabályozási változásról van szó, a nyitottsággal, lojalitással és együttműködéssel működő vállalatok gyorsabban és hatékonyabban reagálnak. Ezek az emberi kapcsolatok ugyanolyan fontosak a rugalmaság szempontjából, mint bármely gép vagy rendszer.

Hogyan tervezzük meg a gépek integrált biztonsági rendszerét már az üzembe helyezés előtt?

2025. május 20. A biztonság minden modern gyártó- vagy csomagolósor létfontosságú eleme. A biztonsági rendszerek megvédik a munkavállalókat, és megakadályozzák, hogy a meghibásodások kárt tegyenek az értékes termékekben és berendezésekben. Ha probléma merül fel, egy jó biztonsági rendszer leállítja a gyártósort, hogy elkerülje a lehetséges baleseteket, ami lehetővé teszi a gyártósor gyors újraindítását is.

Az akkumulátor alapú jövő biztosítása automatizált újrafeldolgozással

2024. december 17. Ahogy a COP 28 konferencián kitűzött célok elérése érdekében a fosszilis tüzelőanyagoktól való függőséget magunk mögött hagyva egyre inkább áttérünk a tisztább energiatechnológiákra, az akkumulátorok döntő szerephez jutnak a megújuló energiaforrások arányának növelésében, mind az energiamix, mind a közlekedés villamosításának terén.Ez a folyamat jelentősen megnövelte az akkumulátorpiacon jelentkező keresletet, különösen két szektorban: az energiaiparban és a közlekedésben. A Nemzetközi Energiaügynökség (International Energy Agency, IEA) szerint az energiaszektor az akkumulátorok iránti teljes kereslet több mint 90%-áért felelős. Az ügynökség jelentése szerint 2023-ban az energiaszektor akkumulátoros kapacitása éves szinten több mint 130%-kal nőtt, világszerte összesen 42 gigawattal (GW) bővítve az elektromos hálózatokat. Az akkumulátorok esetében az energiatárolás egyre jelentősebb alkalmazási területet jelent, mivel lehetővé teszi a megújuló energiaforrásokból nyert energia tárolását, és várhatóan a jövőben egyre fontosabb szerepet fog játszani. A közlekedési ágazatban ugyanakkor az akkumulátorok elősegítették az elektromos autók, kerékpárok, teherautók, buszok és más akkumulátoros járművek elterjedését.

PPWR: Miért létfontosságú a láncon átívelő együttműködés, a nyomonkövethetőség és az intelligens csomagolás?

2024. szeptember 24. Az Eurostat adatai szerint 2021-ben az EU-ban élő minden egyes személy 188,7 kg csomagolást termelt, ami majdnem 32 kg-mal több, mint a 2011-es adat. Ebben az időszakban a műanyag csomagolási hulladék mennyisége 27%-kal nőtt. Miközben az újrahasznosítási arány is nőtt, a műanyag csomagolások nagy részét még mindig nem hasznosítják újra – a legfrissebb statisztikák szerint Európában csak néhány ország ér el 50%-os arányt a műanyagok újrahasznosítását illetően. Felismerve, hogy a meglévő jogi keretrendszer nem mozdítja elő a csomagolási hulladék mennyiségének csökkentését, a bizottság 2022-ben a csomagolásról és csomagolási hulladékokról szóló 2018. évi irányelv (PPWR) felülvizsgálatát javasolta.A felülvizsgált PPWR várhatóan az év végéig lép hatályba, és alapvetően változtatja meg a csomagolás tervezésének, fogyasztásának és hulladékkezelésének módját. Az aktualizált rendelet széleskörű, de a mögöttes cél a keletkező csomagolási hulladék mennyiségének csökkentése és a csomagolás újrahasznosíthatóságának növelése.

A 4 legfontosabb kihívás, amellyel az EV-gyártóknak szembe kell nézniük a fenntartható jövő felé vezető úton

2024. június 17. Az elektromos járművek (EV-k) az elmúlt években egy szűk piaci szegmensből jelentős ipari erővé váltak. 2023-től csaknem minden ötödik eladott autó elektromos, és eladásaik 3,5 millió egységgel növekedtek – ez 35%-os növekedést jelent az előző évhez képest az IEA 2024-es Globális EV-kilátások (Global EV Outlook) szerint. Ez a gyors növekedés várhatóan folytatódik, és az előrejelzések szerint a feltörekvő piacokon az értékesítés 2024-ben meghaladja a 1 millió darabot, ami 40%-os növekedést jelent 2023-hez képest. A kormányok világszerte a CO2-kibocsátás csökkentésére törekednek, ami felgyorsítja az elektromos járművekre való áttérést.Mit jelent ez az autógyártók számára? Először is azt,, hogy elsősorban az elektromos flották tervezése és gyártása felé kell fordulniuk, amit sok gyártó már el is kezdett. Másodszor, új gyártósorok építését és új gyártási folyamatok elsajátítását is jelenti, ami komoly kihívást jelenthet.Itt jön képbe egy megbízható automatizálási partner. Egy automatizálási szakértővel való együttműködés segíthet az egész iparágra kiterjedő átállás összetettségének kezelésében. A széles technológiai portfólióval, globális támogatással és alapos autóipari szakértelemmel rendelkező OMRON készen áll arra, hogy végigvezesse a gyártókat az elektromos járművek gyártása felé vezető útjukon.Ez a blogbejegyzés az EV-gyártási ágazat legfontosabb kihívásait mutatja be, és azt, hogy az OMRON-nal való együttműködés hogyan nyújthat hatékony megoldásokat:

Az intelligens automatizálás mint a változás egyik eszköze

2024. május 31. A gyártási ágazat felelős a globális ÜHG-kibocsátások¹ mintegy negyedéért, így a közlekedéssel hasonló mértékben a második legnagyobb hozzájárulója a globális szén-dioxid-kibocsátásnak. Ez azt jelenti, hogy a gyártási ágazat szén-dioxid-kibocsátásának csökkentése létfontosságú szerepet játszik az emberiség éghajlatváltozásra gyakorolt hatásának mérséklésében.Éppen itt az ideje annak, hogy a gyártási ágazatra ne problémaforrásként, hanem lehetőségként tekintsünk, amely az automatizálás eszközét kihasználva az éghajlatváltozás megoldásának egyik forrása lehet.Ez tükrözi alapítónk azon meggyőződését, miszerint vállalatunk felelősséggel tartozik azért, hogy visszaadjon valamit annak a társadalomnak, amelyet szolgál. Az OMRON több mint 90 évvel ezelőtt született, az alapítója, Kazuma Tateishi elképzeléséből, miszerint a technológiát egy jobb világ megteremtése érdekében kell használnunk.Tateishi étosza – az életminőség javítása és egy élhetőbb társadalomhoz való hozzájárulás – soha nem volt relevánsabb, mint napjainkban, tekintettel azokra az éghajlati kihívásokra, amelyekkel társadalmunknak szembe kell néznie. De mégis hogyan tud a gyártási ágazat pozitív hatást gyakorolni?

Még ha nem is romlott el, akkor is meg kell javítani

2024. április 4. A napi fogyasztási cikkek (FMCG) gyártásának fenntarthatóbbá tétele az intelligens energiagazdálkodás révén

Gyerünk, hölgyeim! Legyenek bátrak, és fedezzék fel az izgalmas karrierlehetőségeket az automatizálásban!

2024. március 1. Maryam Dolatabadi és Asunción Pastrana Costa tapasztalt automatizálási szakértők az OMRON-nál. A lányokhoz és a nőkhöz szólnak: „Légy bátor, sürgősen szükség van rád az iparban!”

Ipari automatizálás és robotika: még mindig a férfiak világa?

2024. február 7. Milyen ma nőként boldogulni az automatizálás területén? Három, az OMRON Europe-nál dolgozó nő mesél az ipari automatizálás világában szerzett tapasztalataikról, az előttük álló kihívásokról, valamint azokról az eszközökről és támogatásról, amelyek segítették a boldogulásukat.Amikor Wendy Tonks több mint 20 évvel ezelőtt megkezdte mérnöki pályafutását az Egyesült Királyságban, az egyik első alapszabály, amit le kellett fektetnie, az volt, hogy ő nem azért van ott, hogy teát szolgáljon fel.

Mi várható az automatizálás terén 2024-ben? Az OMRON Europe hat, a műszaki változásokat előrevetítő irányvonalainak előrejelzése

2023. december 13. Az elmúlt néhány évben bekövetkezett megrázkódtatások sorozata a fokozott geopolitikai és gazdasági kockázatok új korszakát hozta el. Ez arra készteti a gyártókat, hogy az üzleti modelljeiket alkalmazkodóbbá és rugalmasabbá tegyék, és újragondolják a globális ellátási láncaikat és üzleti kapcsolataikat. Ezzel egyidejűleg egyre nagyobb a nyomás, hogy az ESG (Environmental, Social, Governance) környezeti, szociális és vállalatirányítási elveket beépítsék az operatív döntéshozatalba. A mesterséges intelligencia, az adattudomány, a gyártás digitális leképezése (digital twins) valamint az érzékelő, megfigyelő és képalkotó technológiák mind-mind alapvető fontosságúak lesznek az automatizálási és vezérlési megoldások kifejlesztéséhez, amelyek segíthetnek a gyártóiparnak alkalmazkodni ehhez az új valósághoz. Ebben az összefüggésben szeretném megosztani a hat legfontosabb trendet, amelyek 2024-ben és azon túl is hatással lesznek az ipari automatizálásra és alakítani is fogják majd azt.

A munkaerő fontosságának növelése: Az OMRON fejlesztési koncepciója az európai gyártásban