Stop Losing Production Time to Unreliable Detection

Industrial sensors that actually work when your machines need them most -even in the harshest conditions, with the toughest workpieces, and under constant production pressure.

You've Seen This Before

We Get It: Sensing Shouldn't Be This Hard

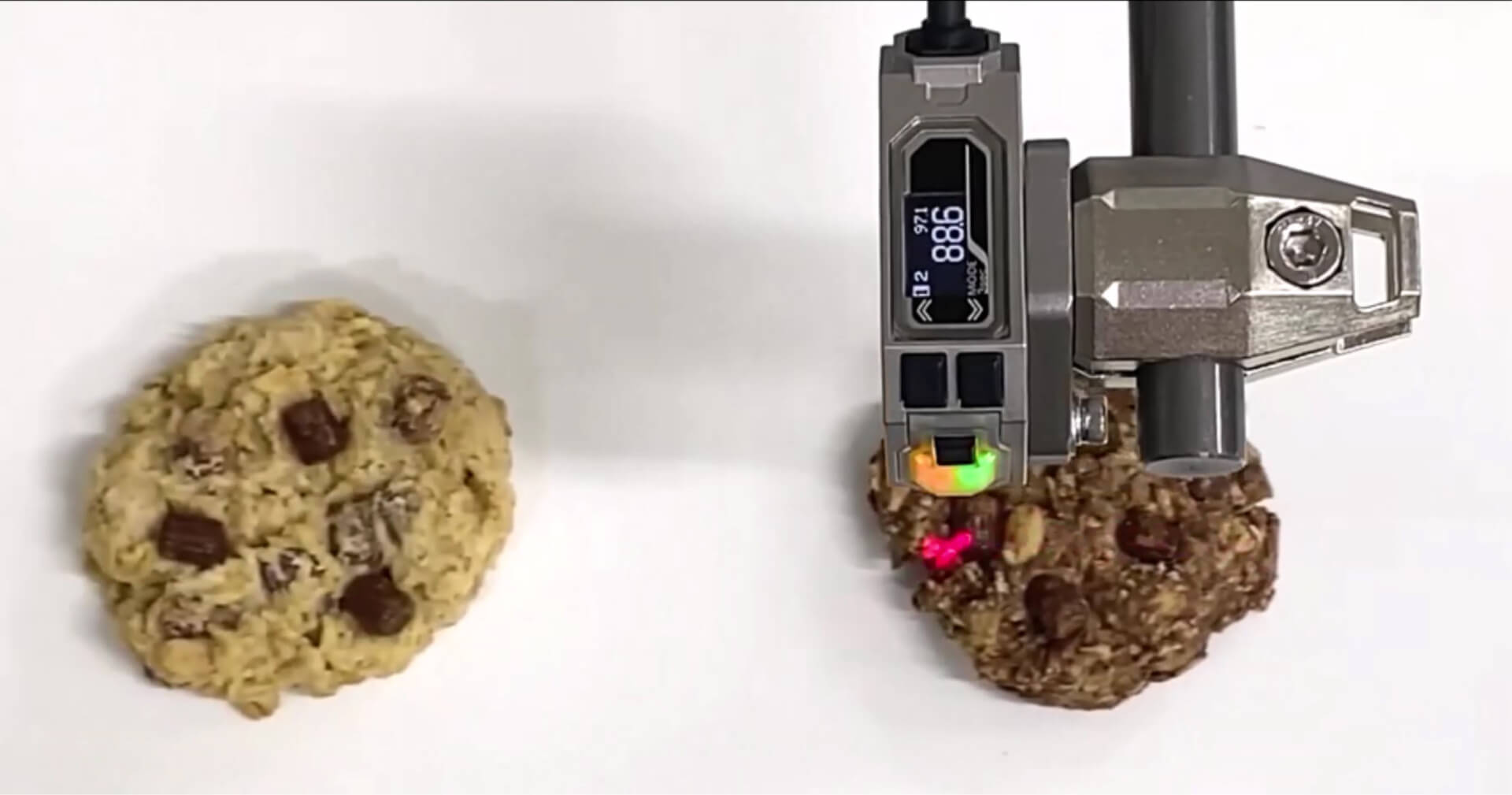

- Changing materials break detection: A sensor that works perfectly on white cardboard suddenly fails when the customer switches to silver foil packaging.

- Harsh environments kill sensors early: Even "industrial-grade" sensors corrode, fog up, or simply stop working after a few months of exposure to washdown chemicals or cutting fluids.

- Integration takes too long: You're dealing with six different sensor brands, each with its own teaching method, own software and support contact. Nothing talks to anything else.

- Selection is overwhelming: Hundreds of sensor models, each with cryptic spec sheets. Which one actually solves your detection challenge?

- False positives waste time: Sensors trigger on reflections, shadows, or vibration—forcing you to add complex filtering logic or physically redesign the machine layout.

One Comprehensive Portfolio. Stable Detection. Seamlessly Integrated.

Real Machine Builders. Real Results.

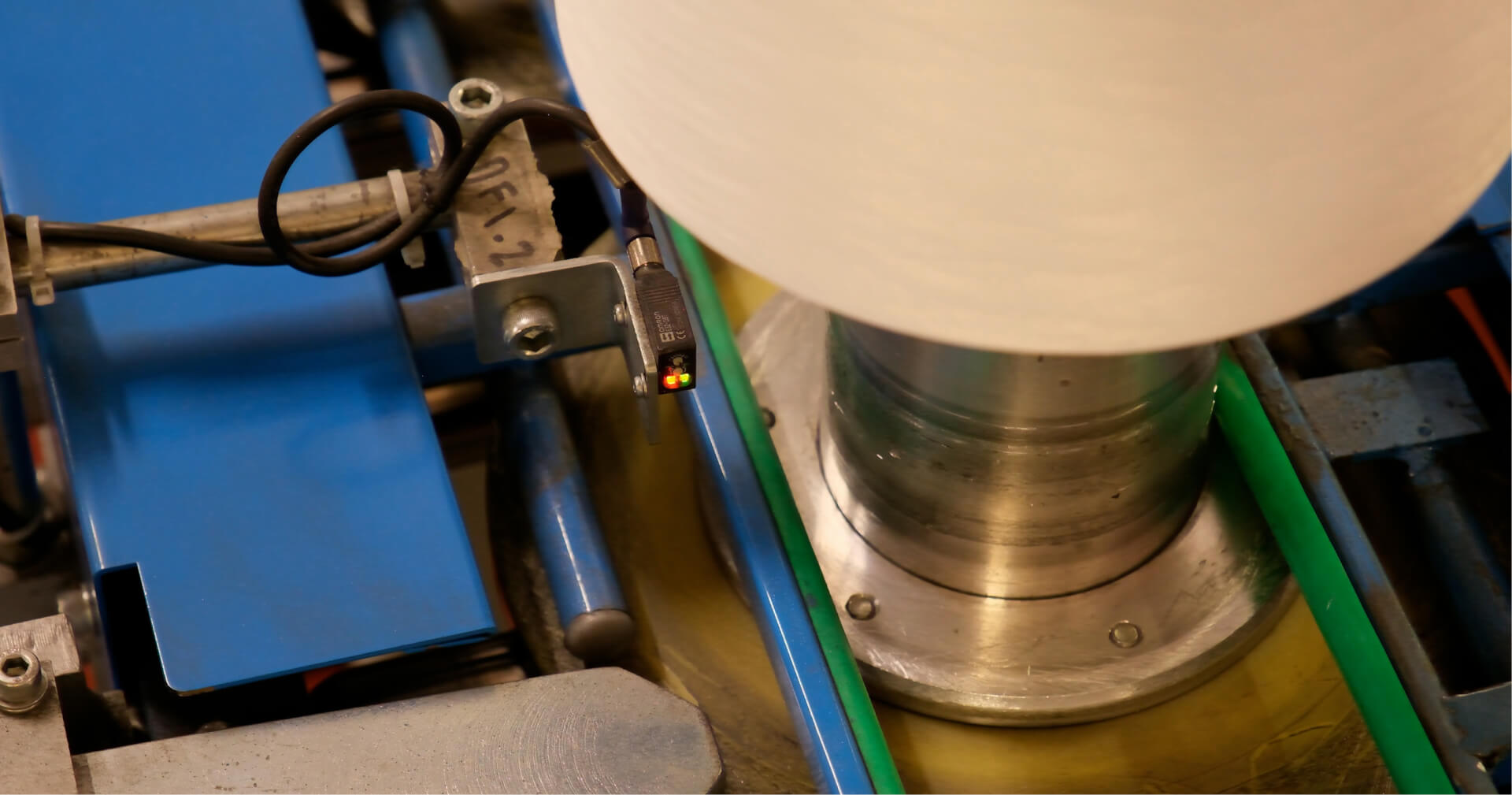

Korteks, one of Europe's largest polyester yarn producers, fully digitalized their textured yarn packaging line using OMRON automation—including photoelectric sensors, proximity sensors, and measurement systems integrated through the Sysmac platform.

"With OMRON's advanced automation and software solutions, our production line has been fully digitalized. We have achieved significant gains in both quality and productivity." — İlker Aytaç, Electronics Manager at Korteks

The numbers speak for themselves: 110,000 bobbins packaged daily, 25% higher capacity, and ROI in just three years.

Korteks Ügyfélreferencia

-

Korteks achieves digital transformation in textured yarn packaging with OMRON automation solutions

Korteks, one of Turkey’s leading polyester yarn manufacturers, has fully digitalized its textured yarn packaging line with OMRON’s advanced automation and software solutions. The project increased production capacity by 25%, reduced labour needs by 30%, and reached a daily packaging capacity of 110,000 bobbins.

04:48

When Italian food manufacturer Cleca needed to boost output on their ready-made broth line, they didn't buy new equipment. Instead, they used OMRON's data service (i-BELT) and smart sensors to identify bottlenecks through data analysis.

By installing continuous monitoring sensors across six production stations and analyzing real-time data, they pinpointed inefficiencies that traditional observation missed. The result? 8% productivity improvement and over 800,000 cartons per month—all from the existing line.

-

From data to manufacturing: How OMRON's i-BELT revolutionized efficiency at Cleca

The Cleca line is the first of its kind in Europe to use i-BELT, the OMRON service that leverages IoT solutions to gather, view and analyze data on site in order to optimize the manufacturing process. This represents a paradigm shift, which, combined with OMRON automation, serves to make projects scalable, replicable and above all consistent. Cleca, the San Martino-based company known for its sweets mix and savory dishes, chose OMRON and its new IoT data analysis service to optimize the efficiency of its ready-made broth line, which was considered insufficient to meet current demand. The upgrade, performed without installing new machinery, has enabled the Mantuan brand to produce over 800,000 cartons from the line per month. Read more about Cleca: Read more about OMRON:

05:12

5 Reasons Machine Builders Choose OMRON Sensors

Seamless Integration with Sysmac Automation

Sensors, PLCs, motion controllers, HMIs, and robots—all engineered together on the Sysmac platform. One software environment (Sysmac Studio). One network (EtherCAT). One controller for machine automation.

Expert Support Across Europe

Local support in every major European country. Engineers who understand your industry. Hands-on PoC's at our Automation Centers where you can test with real workpieces before committing. Training programs. We're not just a sensor supplier—we're your partner in building reliable machines.

Beyond Detection: Using Sensor Data to Optimize Production

- Energy consumption: Sub-metering reveals where power is wasted

- Efficiency metrics: Track actual uptime and cycle times vs. targets

- Quality data: Catch defects inline, before they ship

- Maintenance signals: Predict failures before breakdowns occur

- Real production cost: Calculate true cost per part, per order

OMRON integrated sensing products, a selection

-

Végálláskapcsolók különféle felszerelési alakkal és távolsággal

-

E2E NEXT közelítéskapcsoló

-

Általános célú, hengeres száloptikai érzékelőfejek

-

Fejlett tárgyreflexiós fotoelektromos érzékelők

-

Nagyteljesítményű színes jelölés érzékelő

-

Nagyteljesítményű színes jelölés érzékelő

-

Miniatűr méretű forgó jeladó

-

IoT áramlásérzékelők

-

IoT nyomásérzékelők

-

E9NC-T tapintó érzékelő

-

Lézeres elmozdulásérzékelő